Price :

QTY :

There are items

in your cart

CART TOTALS :

Your shopping bag is empty

Go to the shop

Through the eyes of a designer, hands of a maker and heart of an artist.

My work is for anyone who is looking for thoughtfully handcrafted daily objects. Every piece I craft has a purpose which primarily is to satisfy anyone's desire to eat or drink out of a unique, well crafted vessel. All my functional ware is crafted using a mid-fired clay body that fires at a minimum temperature of 1223 degree Celsius. I formulate my own glazes that are strictly non toxic and have a semi matte finish. Every mug or bowl takes up to roughly a total of 33 hours of various processes, attended or unattended to, from a lump of clay to the final product.

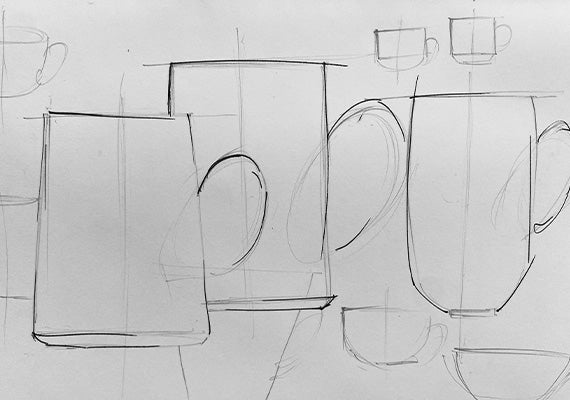

Every collection has a design process backing its foundation. I aspire to create new objects on a regular basis to ensure exclusivity of each product. From the inspiration to the generation of an idea and then execution of the complexity of thoughts to a simple form that follows function with a tinge of an exclusive visual experience is what sets my work apart.

To prepare the clay for moulding, I need to intensively wedge the clay to ensure even consistency of the lump to avoid any mishaps during the process of making.

Wedging the clay is the most essential part of pottery making as any air pockets in the clay could lead to destruction in the midst of the making process.

I use two techniques to construct my objects. Wheel throwing is when I use the potter's wheel to make my objects. It requires great balance and sensitivity to be able to throw objects as thin as possible.

Hand building is when I use processes like coiling or slab rolling to construct the desired object. I need to work on the slab or coil with delicate hands to ensure its thinness and therefore the lightweightness.

After the desired shape is formed, the extra clay needs to be trimmed out of the object to complete it with finesse. The key to this process lies in a deep understanding of the material and it's thickness after it's formed into an object. This process ensures the final weight of the object which needs to be evenly walled from top to base.